Thın mınds — bold solutıons

- Home

- Supply

- HPU unit

Resato High Pressure Technology: High Pressure Applications

Pressure testing: Hydrostatic pressure testing

HPU-sep: Separated test control system

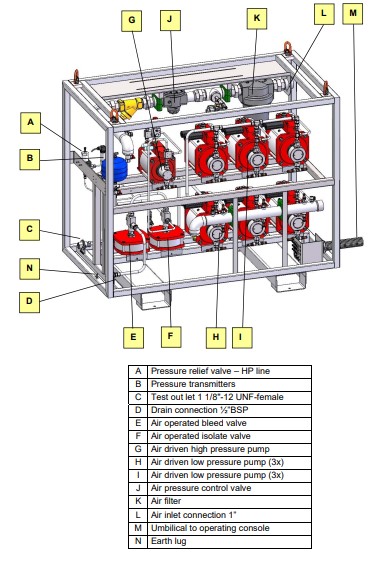

HPU-sep

A HPU separate (HPU-sep) can give you maximum safety during the process of testing objects. The HPU is a separated workshop test control system that is available in different configurations. Which gives you the opportunity to find the HPU system that fits your specific test requirements. With the HPU-sep you can create a test bay setting. The high-pressure test system and the test object are positioned in the test bay and the HPU-sep control panel is placed in a separate control room. This results in a fully separated setup with no high-pressure components outside of the test bay, which offers you safe test circumstances.

Our customers that use similar unit:

BMS: High flow high pressure pump

Outlet pressure range: 4,200 bar (60,000 psi)

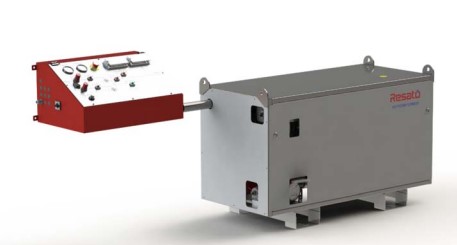

BMS

The BMS mobile pump system enables the testing of objects at different locations in a workshop or at field locations. The wheels or forklift pockets make the BMS much easier to move in comparison to standard workshop units. This high flow / high pressure system enables adequate testing and adapts ideally to your specific requirements for testing large volumes of objects at high pressure. The BMS is generally equipped with two air driven pumps, thus accelerating your operational process. To test objects even quicker, the standard high flow high pressure pump integrated into the BMS can be expanded with a high flow low pressure air driven pump.

Additionally, BMS can be equipped even more than two air driven pumps based on your requirements.

Our customers that use similar unit:

RPS: High pressure power pack

Outlet pressure range: Up to 4,200 bar (60,000 psi)

Flexibility: Portable and easy to move

Mediums: Suitable for pressurizing oil, water or other fluids

RPS

Portable power pack type RPS is a self-contained air-driven system of proven design. Not only can it be used to pressurize valves, fittings, hoses, piping, vessels and wellhead equipment, but it is also suitable for supply of hydraulic power to operate cylinders, presses, rams, jacks, bolt tensioners and actuators. Water, oil or an emulsion of both can be used as the high-pressure medium. Other applications such as chemical injection can be carried out as the system is suitable for a wide range of chemicals.

Our customers that use similar unit:

MPS: Portable mini pump

Outlet pressure range: Up to 2,500 bar (36,250 psi)

Operation: All operating features panel mounted

Mediums: Suitable for pressurizing oil, water or other fluids

MPS

The MPS is a handy portable air driven mini pump that can be easily carried because of its weight (less than 17 kg with a filled tank) and size (405 x 308 x 365 mm). Although this mini pump is small in size and low in weight, it is very suitable for the pressure testing of objects for pressure ranges up to 1,800 bar at 7 bar air-drive pressure and 2,500 bar at 10 bar air drive pressure. Through its pressure supply capacity, it is possible to manually drive the pump with a detachable hand lever if you are in a situation when air pressure is not available. The medium for pressurizing objects with this test system can be a fluid such as water or oil.

Our customers that use similar unit:

HPU-CC: High pressure pump system

Outlet pressure range: Up to 7,000 bar (101,500 psi)

Capacity range: Up to 50 liters per minute

Operation: Computer-controlled

HPU-CC

The HPU-CC Series is a fully-automated high pressure test system for workshop owners who perform many testing activities and require quality certification and traceability. The system can be used for pressure testing on valves, relief valves, safety valves, hoses, completions, well head components, and for hydroforming and filling applications. To reduce operator error, the software allows for user-management and test recipe creation. The execution of tests requires less time as the objects need be connected and the test procedure is started with a push of a button. A certificate can be exported into other software using APIs or exported by PDF. The reliability of the system is established by selecting components that harmonize together and create performance that lasts. Our systems include engineered pumps, intensifiers, valves and fittings, and more from Resato. The performance of the HPU-CC Series can be enhanced using a multi-pump or intensifier set-up that reduces pressure build-up time and improves reliability. The HPU-CC Series can be tailored to your specific high pressure application. Please contact our experts for more information.

Our customers that use similar unit:

Benefits & Features

- Fully automatic test cycle performance that saves testing and setup time

- Ergonomic, safe and user-friendly design allows for healthy use and quick training

- Low noise level

- Suitable for various test mediums, due to Resato pumps

- Flexibility in scaling production through modular setup of the system and software for testing procedures

- Integration in customer processes with product options and software APIs

- Bespoke setup (hardware and software)

- All parts made of non-corrosive materials to prevent corrosion in the system

- Easy and low-cost maintenance through knowledge base access and product design

- Proven reliability due to selected components that harmonize together

Application Areas

- Hose testing

- Oil & Gas industry

- Hydrostatic testing

- Leak testing

- Hydroforming

- Automotive testing

- Autofrettage

- Food preservation research

- Hydraulic testing

- Controlling

Options

- Pre-fill systems

- Combination system with high pressure gas test systems

- Safety systems

- Built-in tank(s)

- Test enclosures

Pressure testing: Gas pressure testing

RBS: High pressure gas booster pack

Outlet pressure range: Up to 1,300 bar (19.000 psi)

Flexibility: Portable and easy to move

Mediums: Suitable for a wide range of gases

RBS

Portable gas booster pack type RBS is designed to compress gas up to 1300 bar. Not only can it be used to pressurize valves, fittings, hoses, piping, vessels and wellhead equipment, but it is also suitable for gas supply for cylinders, presses and actuators. Compressed air used as a power drive offers advantages over use of other drives. The risk of excessive heat, flame, spark or shock are reduced considerably. The RBS as a standard is available in 8 pressure ranges with a single-acting, double-acting or two-stage gas booster. As an option, the system can be fitted with a chart recorder and a USB data acquisition system. The resulting chart can be used as a test certificate.

BOOSTER

The unique design high pressure air-driven booster makes the compressor operate at a low noise level. The boosters are used for pressure testing with gases, industrial gas process feeds, gas charging of accumulators and gas bottles, and other applications. The high-pressure seals can be replaced without disassembling the complete booster.

Our customers that use similar unit:

Pressure testing: Pressure test bays

LTB: Long test box

Outlet pressure range: Various pressure ranges

Materials: Double plated side walls and 20 mm lid

Mediums: Fluids only

LTB

With the modular designed test box, a variety of objects can be safely pressurized, tested and monitored with minimal loss of valuable workshop space. The simplicity of the hydraulically opened lid and integrated thick walled plated steel, ensures a safe test environment for the operator in the workshop. The lid has a door lock and a door switch safety system. By use of a dual pump setup and multiple pressure transmitters the test box can generate test certificates for a wide range of test pressures.

Benefits & Features

- Reduce testing time of objects via pre-filling pump and multiple pump setup

- To ensure safe operating, a locking mechanism is integreated into te text box and the text box can only be pressurize when the lid is closed

- Camera system integrated in testbox

- Forklift pockets, to move the testbox around easily

- Sump pit on testbox floor to pump fluids back to reservoir, enabling re-use of test fluid

- Hydraulic cylinders to open and close the lid easily

- Can be designed according to your general safety design criteria

Application Areas

- Hydrostatic pressure testing

- Cycle testing

- Leak testing

Options

- Additional control lines

- Additional length in 5-meter sections

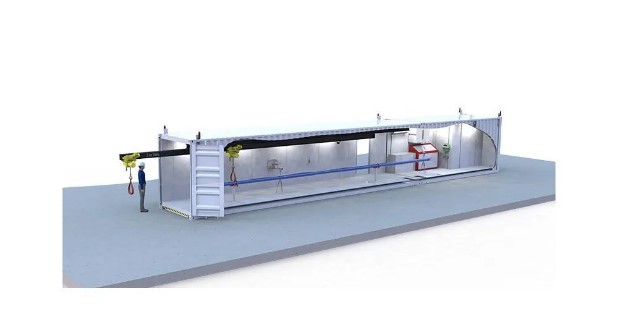

PPU: Containerized pressure test bay

Outlet pressure range: Various pressure ranges

Materials: Double plated side walls and 20 mm lid

Mediums: Fluids only

LTB

With the modular designed test box, a variety of objects can be safely pressurized, tested and monitored with minimal loss of valuable workshop space. The simplicity of the hydraulically opened lid and integrated thick walled plated steel, ensures a safe test environment for the operator in the workshop. The lid has a door lock and a door switch safety system. By use of a dual pump setup and multiple pressure transmitters the test box can generate test certificates for a wide range of test pressures.

Benefits & Features

- Reduce testing time of objects via pre-filling pump and multiple pump setup

- To ensure safe operating, a locking mechanism is integreated into te text box and the text box can only be pressurize when the lid is closed

- Camera system integrated in testbox

- Forklift pockets, to move the testbox around easily

- Sump pit on testbox floor to pump fluids back to reservoir, enabling re-use of test fluid

- Hydraulic cylinders to open and close the lid easily

- Can be designed according to your general safety design criteria

Application Areas

- Hydrostatic pressure testing

- Cycle testing

- Leak testing

Options

- Additional control lines

- Additional length in 5-meter sections

Our customers that use similar unit:

All our customers trust our products & services for Pressure testing: